The latest video shows how to make soles using patterns with polymer clay. It is actually one of the easiest ways of making soles I have figured out so far, if you don't count the trouble of making the card stock supports. Then again, you can reuse those and make more than one pair of soles before using them for shoe soles as well.

Here are the finished shoes, which are also shown at the end of the video.

|

|

|---|

Showing posts with label polymer clay. Show all posts

Showing posts with label polymer clay. Show all posts

Tuesday, May 13, 2014

Saturday, April 12, 2014

Plaster casting continued

I used the molds for plaster casting and also experimented on using a latex mold to make polymer clay heels. I had never done that before, but thought it was worth trying.

Labels:

heels,

latex,

plaster casting,

polymer clay,

video

Wednesday, April 2, 2014

Flat soles using MoldMaker

In one the old videos, I made flat soles for the Baha Cat using polymer clay with a mold. This new video is about making flat soles using mold making clay and polymer clay. The doll for which I'm making the soles is again Baha Cat, although near the end, I'm also showing a mold for male Monster High dolls and some soles I made using it.

Labels:

baha cat,

flat feet,

mold making,

polymer clay,

video

Friday, March 28, 2014

Making a mold for heels using MoldMaker

The following video shows my attempt on making heels using a mold made of mold making clay and also an experiment on making a two-part mold with the clay.

By the way, the word "mould" or "mold" is really bugging me, because of the two ways of writing it. I have decided to stick with "mold" from now on as that is what I am using in the book and because the clay is called MoldMaker.

By the way, the word "mould" or "mold" is really bugging me, because of the two ways of writing it. I have decided to stick with "mold" from now on as that is what I am using in the book and because the clay is called MoldMaker.

Labels:

heels,

mold making,

polymer clay

Thursday, July 11, 2013

Miscellaneous stuff

I haven't done anything new for a while, but there are some things from last year that I haven't posted yet. First pair is Monster High wedges made of Cernit/Fimo and some lace. The method of making the soles is the one explained in this blog post. These are very simple shoes with just the wedge soles, insoles made of cardboard and leather, and some lace.

I made these shoes specifically for the Grayscale Frankie and you can see her wearing them in the story The Not So Grim Reaper.

The next two are variations of the Leopard print shoes for Monster High dolls.

The last Monster High pair is made of what was left of the card-woven band I used for Nefera's shoes.

Finally, there's the first pair I've ever made for a Novi Stars doll, in this case, Una Verse. I made these to go together with a dress I crocheted for the doll using the same sewing threads as in the card-woven bands. Otherwise, they're just leather, cardboard, and pieces of wood for heels.

I made these shoes specifically for the Grayscale Frankie and you can see her wearing them in the story The Not So Grim Reaper.

The next two are variations of the Leopard print shoes for Monster High dolls.

The last Monster High pair is made of what was left of the card-woven band I used for Nefera's shoes.

Finally, there's the first pair I've ever made for a Novi Stars doll, in this case, Una Verse. I made these to go together with a dress I crocheted for the doll using the same sewing threads as in the card-woven bands. Otherwise, they're just leather, cardboard, and pieces of wood for heels.

Labels:

card weaving,

cork,

monster high doll,

novi stars doll,

polymer clay,

wedge soles

Friday, September 14, 2012

More experiments with polymer clay

I was wondering if I could make something like the modified plastic castings in the previous post, but use polymer clay. I made a similar mold (only taller) using cardboard and cut pieces from the sides, so I could cut the clay after filling the mold.

Then I covered those openings with pieces of cardboard attached with adhesive tape. This helps in filling the mold.

When the mold was full, I removed those extra pieces.

Then I cut along the edges of the openings. That wasn't easy as the clay was a bit too soft even after a few hours in a fridge. Soft clay is easier when filling the mold, but makes cutting more difficult. The surfaces required some work after cutting to make them even.

Here are the soles after baking and removing the molds. I'm not quite happy with the shape, so I think these will have to be cut and sanded quite a bit. Still, I've got two soles of similar shape and size to work with, which is more than I could do without using molds.

Then I covered those openings with pieces of cardboard attached with adhesive tape. This helps in filling the mold.

When the mold was full, I removed those extra pieces.

Then I cut along the edges of the openings. That wasn't easy as the clay was a bit too soft even after a few hours in a fridge. Soft clay is easier when filling the mold, but makes cutting more difficult. The surfaces required some work after cutting to make them even.

Here are the soles after baking and removing the molds. I'm not quite happy with the shape, so I think these will have to be cut and sanded quite a bit. Still, I've got two soles of similar shape and size to work with, which is more than I could do without using molds.

Labels:

monster high doll,

platform,

polymer clay

Tuesday, September 11, 2012

Wedge soles using polymer clay

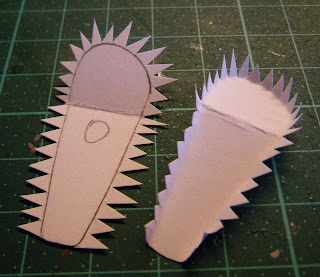

I decided to try, if the method I've been using for heels would also work with wedge soles. I have previously made this kind of soles using E-Z Water plastic that needs to be melted. With the plastic, I used a metal mold, but as polymer clay needs to be baked in the oven, I used cardboard for these.

I started by making a pattern. These soles are for Nefera, so I had to start from scratch.

Previously, I have made the back of the heel curved, but this time, I decided to try angles.

When using metal, the insoles are attached with adhesive tape, but as these molds will go into the oven, plastic isn't an option. So, I cut flaps all around the insoles, except at the back, where there needs to be a hole in the mold. The flaps need to be narrow, so the curves will come out nicely.

The next picture shows how to glue the insoles in place. This can be a bit messy with glue spreading all over your finger tips, but fortunately, only the inside of the mold needs to stay neat.

Then it was time to test that the arch of the foot is correct. The additional piece of cardboard on the side of the mold is there to fix a small hole (that particular angle is a bit tricky and if you're not careful, there will be a hole there). Note the hole on top, behind the doll's heel. That hole is there to help you see when the mold is full. When pressing the clay into the mold, only stop when it starts coming out of that hole. Remove any excess before baking the soles.

Here are the molds filled with polymer clay and ready for baking. At this stage, you should check that the bottom is even and that the soles do not lean left or right. Check also that the insole does not bulge. It is easier to fix that at this stage, but you can fix it also after baking, just use a craft knife and cut off any excess.

Finished heels after baking.

I started by making a pattern. These soles are for Nefera, so I had to start from scratch.

Previously, I have made the back of the heel curved, but this time, I decided to try angles.

When using metal, the insoles are attached with adhesive tape, but as these molds will go into the oven, plastic isn't an option. So, I cut flaps all around the insoles, except at the back, where there needs to be a hole in the mold. The flaps need to be narrow, so the curves will come out nicely.

The next picture shows how to glue the insoles in place. This can be a bit messy with glue spreading all over your finger tips, but fortunately, only the inside of the mold needs to stay neat.

Then it was time to test that the arch of the foot is correct. The additional piece of cardboard on the side of the mold is there to fix a small hole (that particular angle is a bit tricky and if you're not careful, there will be a hole there). Note the hole on top, behind the doll's heel. That hole is there to help you see when the mold is full. When pressing the clay into the mold, only stop when it starts coming out of that hole. Remove any excess before baking the soles.

Here are the molds filled with polymer clay and ready for baking. At this stage, you should check that the bottom is even and that the soles do not lean left or right. Check also that the insole does not bulge. It is easier to fix that at this stage, but you can fix it also after baking, just use a craft knife and cut off any excess.

Finished heels after baking.

Labels:

mold making,

monster high doll,

polymer clay,

wedge soles

Wednesday, September 5, 2012

Making modeling clay heels

My main problem with modeling clay is that I cannot make two identical pieces without a pattern or mold. So, I have solved the problem of making heels by using a cardboard mold.

This time I was making heels for 16" Miss Piggy's shoes. The photo below shows the cardboard insole with an empty mold for the heel.

The hardest part is making the pattern for the mold. You can see the basic form below, but it is very much trial and error. Once you've got the pattern right, draw the required number of them on cardboard, fold the front parts as shown, and cut out the pieces. You can make the folds after cutting, but I find this order easier.

Curve the back and sides of the heels using a suitable round object, for example, a marker pen.Then glue the front as shown. The result is the neatest, if the lower flap (the one that goes inside, against the modeling clay) covers the entire width of the heel front. If it doesn't, you'll get a visible seam in the modeling clay (see the last photo of this blog post).

When the glue is dry, pack the molds full of modeling clay. Press it tightly to avoid any gaps, but be careful, so you won't crush the mold. When the mold is full, use a craft knife to cut off any modeling clay that exceeds the top or bottom of the mold, and make sure the form of the heel is the way you want it.

Bake the heels in the oven according to the instructions given in the packaging of the modeling clay you're using. After getting them out of the oven, remove the cardboard immediately (as soon as you can handle the hot pieces). If you let the pieces cool down, the cardboard will be a lot harder to remove. If you're going to cover the heels with fabric, leather, etc., you can also leave the cardboard in place (especially, if you have used leftover pieces of clay of various colors and want to make sure that won't show through the material used for covering the heels).

Here are the finished heels for Miss Piggy.

The top of the heel may be convex even when you have cut it before baking. If that is the case, just use a craft knife to remove any extra material. This has the added benefit that glue will hold better, if the surface is cut or sanded after baking.

This time I was making heels for 16" Miss Piggy's shoes. The photo below shows the cardboard insole with an empty mold for the heel.

The hardest part is making the pattern for the mold. You can see the basic form below, but it is very much trial and error. Once you've got the pattern right, draw the required number of them on cardboard, fold the front parts as shown, and cut out the pieces. You can make the folds after cutting, but I find this order easier.

Curve the back and sides of the heels using a suitable round object, for example, a marker pen.Then glue the front as shown. The result is the neatest, if the lower flap (the one that goes inside, against the modeling clay) covers the entire width of the heel front. If it doesn't, you'll get a visible seam in the modeling clay (see the last photo of this blog post).

When the glue is dry, pack the molds full of modeling clay. Press it tightly to avoid any gaps, but be careful, so you won't crush the mold. When the mold is full, use a craft knife to cut off any modeling clay that exceeds the top or bottom of the mold, and make sure the form of the heel is the way you want it.

Bake the heels in the oven according to the instructions given in the packaging of the modeling clay you're using. After getting them out of the oven, remove the cardboard immediately (as soon as you can handle the hot pieces). If you let the pieces cool down, the cardboard will be a lot harder to remove. If you're going to cover the heels with fabric, leather, etc., you can also leave the cardboard in place (especially, if you have used leftover pieces of clay of various colors and want to make sure that won't show through the material used for covering the heels).

Here are the finished heels for Miss Piggy.

The top of the heel may be convex even when you have cut it before baking. If that is the case, just use a craft knife to remove any extra material. This has the added benefit that glue will hold better, if the surface is cut or sanded after baking.

Labels:

miss piggy,

mold making,

polymer clay

Monday, May 4, 2009

Mould making: Flat soles with Sculpey Mold Maker

I am going to make some moulds for doll shoe soles. There is some info on my home page, but I'll go into more detail here. Also, I know a lot more now than I did when I wrote those instructions.

I'll start with flat soles for Baha Cat's boots. The boots will be similar to the ones I have made earlier with cork soles for a lot bigger doll.

First I drew a pattern for the foot. Then I cut one piece of foam core and several layers of cardboard using the pattern.

I glued the cardboard pieces together, cut a heel out of that piece and glued it in place to the foamcore sole.

Then I drew a pattern for the sole in the rest of the multilayer piece, cut out the pieces and glued them to the foam core sole.

When the glue was dry, I painted the sole. I used gloss acrylic paint and applied several coats.

Now I had the model ready and it was time to make a mould. I used Sculpey Mold Maker, because that is what was available. There may be other clays similar to it.

See the instructions in the package for making the mould. I noticed that it is easier to make the mould, if you cool the clay in the fridge for some time (after shaping it to suitable size) before pressing the object into it.

Bake the clay in the oven according to the instructions in the package. When the mould is cool, mist it with water and press a piece of polymer clay into it. As you may guess from the amount of water, I didn't actually mist the mould, I just put it under the tap and then shook off the extra water. It works fine that way.

After making the desired amount of pieces, bake them in the oven. I used red clay to get better pictures. The actual soles are going to be black or brown, but I do have some red leather, so maybe the Baha Cat is going to get red boots as well.

This mould was easy to make. I'm also planning on making moulds for casting plastic soles for Sybarite's shoes, but more about that later.

Finnish post is here.

I'll start with flat soles for Baha Cat's boots. The boots will be similar to the ones I have made earlier with cork soles for a lot bigger doll.

First I drew a pattern for the foot. Then I cut one piece of foam core and several layers of cardboard using the pattern.

I glued the cardboard pieces together, cut a heel out of that piece and glued it in place to the foamcore sole.

Then I drew a pattern for the sole in the rest of the multilayer piece, cut out the pieces and glued them to the foam core sole.

When the glue was dry, I painted the sole. I used gloss acrylic paint and applied several coats.

Now I had the model ready and it was time to make a mould. I used Sculpey Mold Maker, because that is what was available. There may be other clays similar to it.

See the instructions in the package for making the mould. I noticed that it is easier to make the mould, if you cool the clay in the fridge for some time (after shaping it to suitable size) before pressing the object into it.

Bake the clay in the oven according to the instructions in the package. When the mould is cool, mist it with water and press a piece of polymer clay into it. As you may guess from the amount of water, I didn't actually mist the mould, I just put it under the tap and then shook off the extra water. It works fine that way.

After making the desired amount of pieces, bake them in the oven. I used red clay to get better pictures. The actual soles are going to be black or brown, but I do have some red leather, so maybe the Baha Cat is going to get red boots as well.

This mould was easy to make. I'm also planning on making moulds for casting plastic soles for Sybarite's shoes, but more about that later.

Finnish post is here.

Labels:

baha cat,

flat feet,

mold making,

polymer clay

Tuesday, April 28, 2009

White leather shoes for American Model

I had a piece of thick white leather, which I had not even tried to use, because it was so stiff. I decided to try something very simple in which the parts folded below the insole would be as straight as possible. The result was the following structure:

Because the leather was very thick, I had to glue filler pieces to the underside of the insole. This way, the outer sole will be smooth even if it is not made of very thick leather.

I painted the cut edges of the leather with white acrylic paint to make them neat. The decorations are stickers, the heels are made of polymer clay and the outer soles are made of brown leather.

Original Finnish post: March 6, 2007

Because the leather was very thick, I had to glue filler pieces to the underside of the insole. This way, the outer sole will be smooth even if it is not made of very thick leather.

I painted the cut edges of the leather with white acrylic paint to make them neat. The decorations are stickers, the heels are made of polymer clay and the outer soles are made of brown leather.

Original Finnish post: March 6, 2007

Labels:

american model,

polymer clay,

stickers,

tonner

Barbie shoes made of polymer clay

I once decided to try if I could make doll shoes using polymer clay. I was using Cernit, because I like it better than Fimo, which tends to get too soft in my hands.

First I formed the clay into a fairly thin sheet and then used a paper pattern and hobby knife to cut out the soles of the shoes. I used the heel part of the same pattern to cut two pieces for each heel. If the clay is difficult to cut neatly, place it in the fridge for a couple of hours to harden. Then it should be easier to cut. Also, the knife needs to be sharp.

I smoothed the edges of the soles, placed the heel pieces in place, and used the doll's feet to check that the form of the soles was correct. Then I baked the soles in the oven. When the soles had been baked and cooled, I added the insole, strap and small decoration.

The insole is probably more important here than when using other materials. Polymer clays have bright colors, so if they stain the doll's feet, it will certainly show. I'm not sure whether they stain or not, but I prefer caution and use an insole that insulates the doll's feet from the clay.

This experiment gave me an idea to try to make an entire shoe out of polymer clay. It should be fine, if you bake the sole first, so you don't need to be too careful with it. Then you could build basically anything on top of that, provided that you take care to check that the shoe will go on and off easily as this kind of shoes won't stretch at all.

It's been a while and I still haven't got into trying that, but maybe I will at some point.

Original Finnish post: January 25, 2006

First I formed the clay into a fairly thin sheet and then used a paper pattern and hobby knife to cut out the soles of the shoes. I used the heel part of the same pattern to cut two pieces for each heel. If the clay is difficult to cut neatly, place it in the fridge for a couple of hours to harden. Then it should be easier to cut. Also, the knife needs to be sharp.

I smoothed the edges of the soles, placed the heel pieces in place, and used the doll's feet to check that the form of the soles was correct. Then I baked the soles in the oven. When the soles had been baked and cooled, I added the insole, strap and small decoration.

The insole is probably more important here than when using other materials. Polymer clays have bright colors, so if they stain the doll's feet, it will certainly show. I'm not sure whether they stain or not, but I prefer caution and use an insole that insulates the doll's feet from the clay.

This experiment gave me an idea to try to make an entire shoe out of polymer clay. It should be fine, if you bake the sole first, so you don't need to be too careful with it. Then you could build basically anything on top of that, provided that you take care to check that the shoe will go on and off easily as this kind of shoes won't stretch at all.

It's been a while and I still haven't got into trying that, but maybe I will at some point.

Original Finnish post: January 25, 2006

Labels:

barbie,

flat feet,

polymer clay

Subscribe to:

Posts (Atom)